Why How to Repair Hail Damage on Metal Roof Matters for Your Home

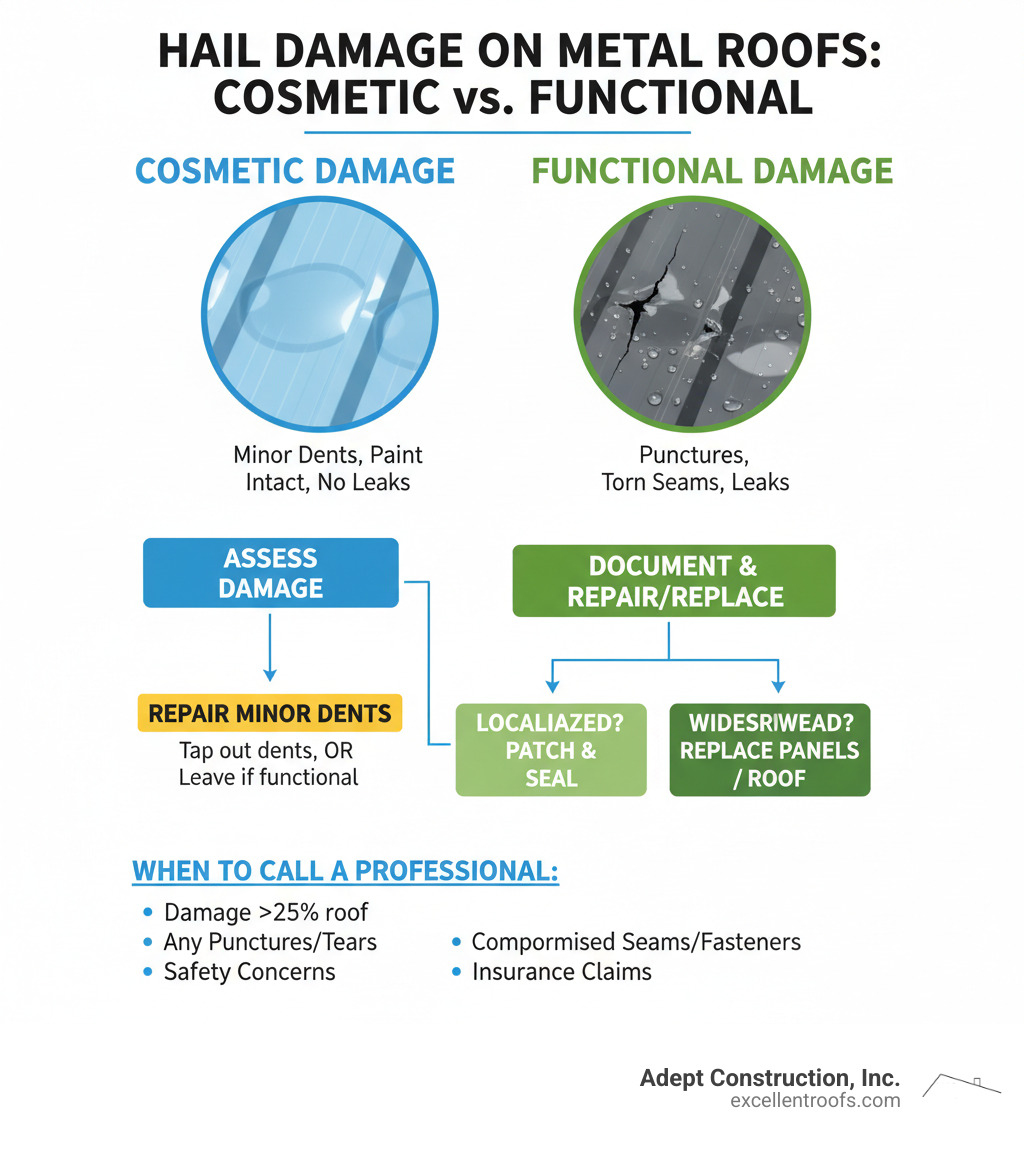

How to repair hail damage on metal roof depends entirely on the severity of the impact. Here’s a quick breakdown:

For Minor Cosmetic Dents (paint intact, no leaks):

- Clean the dented area.

- Use a rubber mallet and wooden block from underneath to gently tap out the dent.

- Consider leaving minor dents if they don’t affect roof function.

For Functional Damage (punctures, torn seams, leaks):

- Document all damage with photos for insurance.

- Clean and scuff the damaged area.

- Cut out severely damaged sections.

- Apply a high-grade urethane or silicone-based sealant.

- Secure a color-matched metal patch over the damage.

- Replace entire panels if damage is extensive.

When to Call a Professional:

- Damage covers more than 25-30% of the roof.

- Any punctures, tears, or compromised seams are present.

- You’re uncomfortable working at heights or lack safety gear.

- An insurance claim is involved.

Metal roofs are built to last 40 to 70 years, but thousands of hailstorms occur annually. While most hail damage is cosmetic—dents that don’t affect performance—ignoring functional damage like punctures or broken seams can lead to leaks and costly water damage. Protecting your home with a durable roofing system begins with knowing what to look for and when to act.

Many insurance policies now include cosmetic damage exclusions, making it critical to distinguish between an unsightly dent and a functional problem that requires immediate repair. As the founder of Adept Construction, Inc., I’ve spent nearly three decades helping homeowners in the Chicago suburbs with storm damage. This guide will help you understand your options for how to repair hail damage on metal roof systems, saving you time and money.

First, Assess the Damage: Identifying Hail’s Impact on Your Metal Roof

After a hailstorm, your first step is a safe and thorough assessment. Never climb onto a wet or icy roof. If you are not comfortable with heights or lack proper safety equipment, perform your inspection from the ground with binoculars. If you do go on the roof, use a harness, non-slip footwear, and have someone on the ground.

Document everything with clear photos from multiple angles. This documentation is critical for any potential insurance claim.

What Are the Signs of Hail Damage?

Hail damage on metal roofing appears in several forms, ranging from minor to severe.

- Dents and Dings: The most common sign, ranging from small pockmarks to large indentations. The size and depth correlate with the hailstone size and metal gauge.

- Scratches and Scuffs: Jagged hailstones can scrape the surface, leaving marks that are typically cosmetic.

- Chipped or Cracked Coating: This is a functional issue. When the protective layer is compromised, the underlying metal is exposed to moisture, leading to rust.

- Punctures: While rare, extremely large hailstones (2.5 inches or more) can penetrate thinner gauge metal. This is severe damage requiring immediate repair.

- Damaged Seams or Fasteners: Hail can loosen seams or dislodge fasteners, creating entry points for water. Cracked rubber washers on fasteners are a common failure point.

- Water Stains: Check your attic for water stains on the underside of the roof deck. This is a definitive sign that your roof’s watertight seal has been breached.

Understanding Damage Types: Cosmetic vs. Functional

The distinction between cosmetic and functional damage determines the repair approach and what your insurance may cover.

Cosmetic damage refers to dents or dings that are purely aesthetic. The protective coating is intact, and the roof’s ability to shed water is not compromised. Many insurance policies now have cosmetic damage exclusions, meaning they won’t pay for repairs that don’t affect the roof’s function.

Functional damage includes any issue that allows or will allow water intrusion. This covers punctures, tears, compromised seams, broken fasteners, or any damage where the protective coating is breached and bare metal is exposed to corrosion. This type of damage requires immediate attention.

The line between cosmetic and functional can be difficult for an untrained eye to see. A small dent might hide a hairline crack in the coating. This is where a professional storm damage assessment is invaluable. Our experienced team can accurately identify all forms of damage, providing a clear report on what needs repair to protect your home.

DIY vs. Professional: Deciding Your Metal Roof Repair Strategy

Once you’ve assessed the damage, you must decide whether to handle the repair yourself or hire a professional. A botched DIY repair can lead to leaks, void your warranty, and cost far more than hiring an expert from the start. However, for minor cosmetic issues, a DIY approach may be feasible.

How to Repair Hail Damage on a Metal Roof: Minor Dents

If you have small, shallow dents where the paint or coating is completely intact, you may be able to improve their appearance. This is a cosmetic fix only and does not restore the metal’s original strength.

- Clean the area with mild detergent and water.

- Access from underneath (if possible, like in an attic). Place a wooden block against the back of the dent and tap it gently with a rubber mallet.

- Consider PDR tools. Paintless dent repair (PDR) tools, designed for cars, can sometimes pull out dents using suction or levers. Patience is key.

If you see any cracks in the paint or the dent is deep, stop. This is functional damage and requires professional expertise.

When to Call a Professional for Repairs

Attempting complex repairs without proper training can void your warranty or lead to a dangerous fall. For significant issues with how to repair hail damage on metal roof systems, professional help is essential.

Call a professional roofer if you see:

- Extensive denting across multiple panels.

- Any punctures or tears, as even small holes can cause major water damage.

- Damaged seams, flashing, or fasteners, which are critical to your roof’s watertight seal.

- You are uncomfortable with heights. Professional roofers have the training and equipment to work safely.

- Your warranty requires it. Many manufacturers mandate professional repairs to keep the warranty valid.

For homeowners in the Chicago suburbs, our team at Adept Construction, Inc. has the specialized tools and expertise for any storm damage repair. Whether you need roof repair in Downers Grove, IL or nearby, we offer free, no-obligation estimates.

The Professional Guide to Major Metal Roof Hail Repairs

When hail damage is functional, professional repair is non-negotiable. The two primary methods are patching and full panel replacement. The choice depends on the extent of the damage, and we always follow manufacturer guidelines to maintain your warranty and ensure a perfect, watertight seal.

How to Repair Hail Damage on a Metal Roof: Punctures and Tears

Punctures and tears are direct entry points for water and must be addressed immediately to prevent interior damage. This is not a DIY project. Here is the professional process:

- Clean and Scuff: We thoroughly clean the area and scuff it with a wire brush to ensure the sealant will bond properly.

- Cut Out Damage: The damaged section is cut out with at least a two-inch margin to ensure we are working with sound metal.

- Apply Sealant: A generous bead of high-quality urethane or silicone-based sealant, formulated for metal roofing, is applied around the opening.

- Secure Patch: A color-matched metal patch of the correct gauge is placed over the sealed opening.

- Fasten and Seal: The patch is secured with long-life fasteners, and another layer of sealant is applied to all edges for a permanent, watertight repair.

The Process for Full Panel Replacement

When a panel has multiple punctures, severe distortion, or compromised seams, full panel replacement is the only reliable solution. This is precision work requiring specialized tools and experience.

- Isolate Panel: We carefully identify and isolate the damaged panel to avoid disturbing the surrounding roof system.

- Remove Panel: Using specialized tools, we remove the fasteners and lift the panel without damaging adjacent panels or interlocking seams.

- Inspect Underlayment: With the panel removed, we inspect the underlayment for water damage or tears. Any compromised substrate is repaired or replaced before proceeding.

- Install New Panel: A new, matching panel (profile, gauge, and finish) is installed according to manufacturer specifications. For more on this, you can review a panel repair process technical bulletin.

- Secure and Seal: The new panel is secured with new fasteners and high-quality sealant on all seams to create a robust, watertight system.

This comprehensive approach is the most effective solution for severe damage and is often a precursor to a full roof replacement in Naperville, IL if the damage is widespread.

Sealing the Deal: Waterproofing and Protective Coatings

After structural repairs, the final step in how to repair hail damage on metal roof systems is ensuring a durable, watertight seal. This is achieved with professional-grade sealants and, in some cases, protective coatings.

Recommended Sealants for Metal Roof Repairs

For metal roof repairs, only use sealants specifically designed for that application. The wrong product will fail quickly.

- Silicone-Based Sealants: These are our top choice due to their excellent UV resistance and flexibility in extreme temperatures. They provide a long-lasting seal for patches and fasteners.

- Urethane-Based Sealants: Known for their superior adhesion and durability, urethanes are ideal for sealing joints and seams where metal surfaces meet.

- Butyl Tape: This reliable product creates a pliable, waterproof barrier under seams and around fasteners, compressing perfectly between metal layers.

A critical technique is to compress the sealant between two pieces of metal and secure it with fasteners. Simply applying sealant to the surface is a temporary fix that will fail.

Can an Elastomeric Coating Fix or Prevent Hail Damage?

Elastomeric coatings are valuable for roof maintenance but are often misunderstood as a repair solution for hail.

What coatings DO:

- Provide excellent UV resistance, protecting the finish from sun degradation.

- Add a seamless, waterproof membrane over the entire roof.

- Seal minor abrasions in the paint to prevent corrosion.

What coatings DO NOT do:

- Fix dents. A coating will conform to the dented surface, not flatten it.

- Add structural strength. It will not restore the metal’s original rigidity.

- Prevent hail damage. While a thick coating might offer minimal resistance to tiny hail, it is not a primary defense. True hail resistance comes from the metal’s gauge and impact rating (UL 2218 Class IV).

An elastomeric coating is a great investment for extending a roof’s life after proper storm damage repairs have been made, but it is not a substitute for them.

Future-Proofing Your Roof: Prevention and Insurance Insights

A metal roof is a smart investment, and protecting it involves proactive choices and knowing how to steer the insurance process after a storm.

How to Minimize Future Hail Damage

While no roof is completely hail-proof, these strategies significantly reduce the risk of damage:

- Choose a High Impact Rating: Select a roof with a UL 2218 Class IV rating, the highest standard for impact resistance.

- Select Thicker Metal: A lower gauge number means thicker, more durable metal. A 24-gauge panel offers much better resistance than a 29-gauge panel.

- Consider Textured Finishes: Textured or patterned finishes are excellent at camouflaging minor dents, making them far less noticeable.

- Schedule Regular Inspections: Visually inspect your roof from the ground twice a year and schedule a professional inspection after any major storm, especially in areas like Naperville, IL known for severe weather.

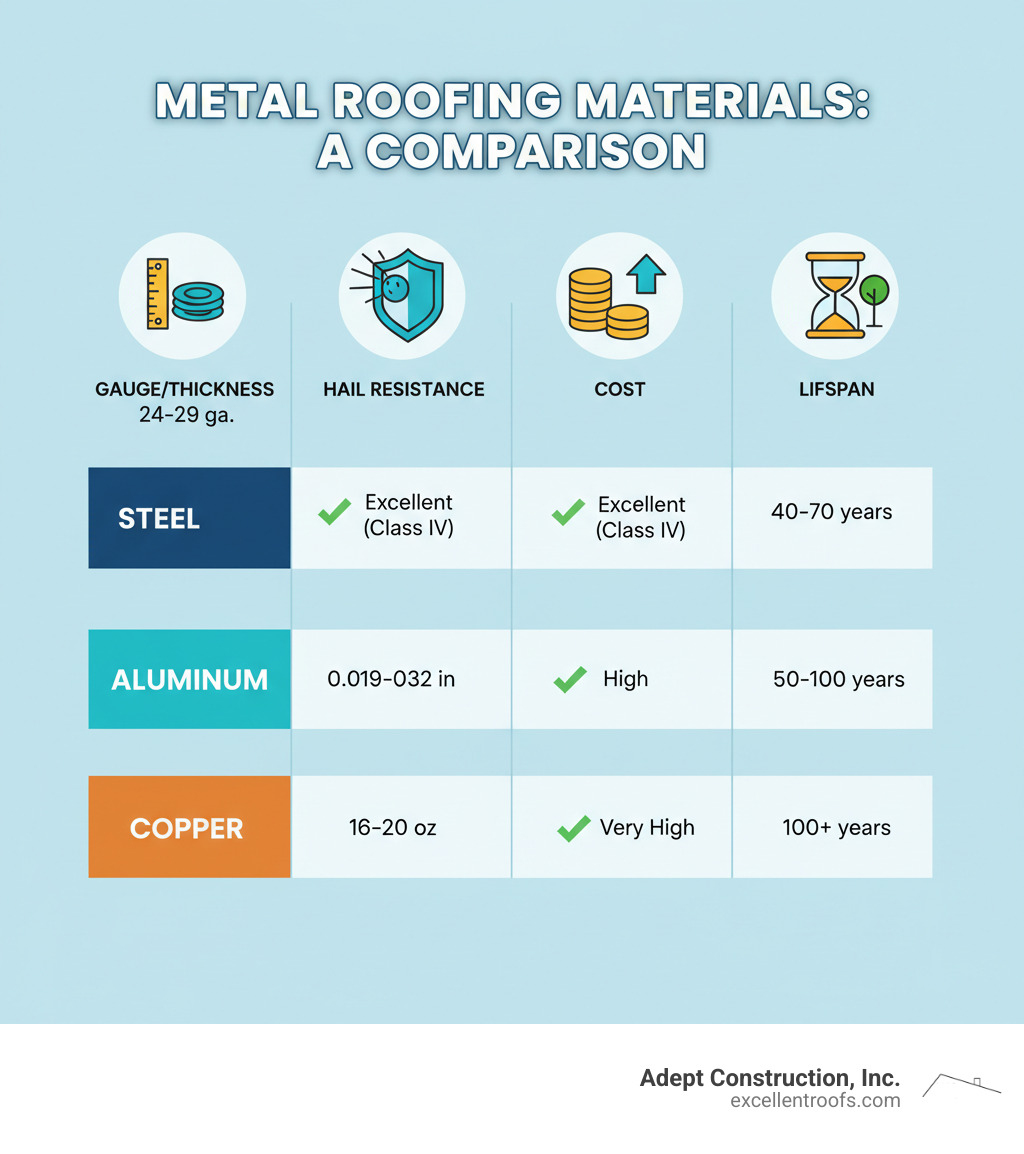

| Material | Gauge/Thickness | Hail Resistance | Cost | Lifespan |

|---|---|---|---|---|

| Steel | 24-29 gauge | Excellent (Class IV) | Moderate | 40-70 years |

| Aluminum | 0.019-0.032 in | Excellent (Class IV) | High | 50-100 years |

| Copper | 16-20 oz | Excellent (Class IV) | Very High | 100+ years |

Navigating Insurance Claims for a Hail Damaged Metal Roof

Dealing with insurance companies can be complex. Following these steps can lead to a smoother process:

- Document Everything Immediately: Take clear, time-stamped photos of all damage to your roof, siding, and gutters. This comprehensive evidence strengthens your claim.

- Contact Your Insurer: Report the damage as soon as possible to start the claims process and get a claim number. With thousands of damaging hail storms in the U.S. annually, prompt reporting is key.

- Have a Roofer Present for the Inspection: This is essential. An insurance adjuster’s goal can be to minimize payouts. We can meet the adjuster on-site to ensure all functional damage is identified and properly documented.

- Understand Your Policy: Review your policy for clauses on hail damage, especially “cosmetic damage exclusions,” which may limit coverage for dents that don’t cause leaks. Knowing your coverage is the first step.

Our team at Adept Construction, Inc. has guided hundreds of homeowners through the insurance claims process for storm damage. We can help you understand your policy and ensure you receive fair compensation for repairs in Downers Grove, IL and the surrounding areas.

Frequently Asked Questions about Metal Roof Hail Damage

Here are direct answers to the most common questions we receive about hail damage on metal roofs.

How much hail damage requires a full roof replacement?

A full roof replacement is typically necessary when damage is widespread (affecting over 25-30% of the surface) or when the roof’s functional integrity is compromised by multiple punctures or seam failures that cannot be reliably patched. If the cost of repairs approaches 50-60% of a new roof’s cost, replacement is often the more financially sound decision. A professional assessment is required to make this determination, as hidden damage can exist.

Will hail dents on my metal roof cause it to rust?

Dents alone will not cause rust if the roof’s protective coating (e.g., Galvalume, Kynar paint) remains intact. Rust forms only when a hail impact is severe enough to crack or chip this coating, exposing the underlying steel to moisture and oxygen. This is why a professional inspection is crucial; an expert can identify whether the coating has been breached, which would turn a cosmetic issue into a functional one that requires sealing to prevent future corrosion.

How does hail damage on a metal roof compare to asphalt shingles?

Metal roofs are significantly more resistant to functional hail damage than asphalt shingles. While metal may dent, it rarely punctures. In contrast, hail can crack asphalt shingles, strip them of their protective granules, and cause bruising that leads to premature failure and leaks. Most metal roofing systems carry a UL 2218 Class IV impact rating—the highest available—and maintain this resistance as they age. Asphalt shingles become more brittle and vulnerable over time, making metal a superior choice for hail-prone regions. Even with dents, a metal roof usually maintains its water-shedding ability, which is not always the case with a hail-damaged shingle roof. For any type of roof, a thorough storm damage assessment is the best course of action.

Get Your Free Estimate for Hail Damage Repair

After a hailstorm, the most important step is a professional inspection to protect your property. At Adept Construction, Inc., our experienced team provides thorough assessments for homeowners throughout Downers Grove, IL, Naperville, IL, and the surrounding Chicago suburbs.

Dealing with storm damage is overwhelming. We simplify the process by helping you understand how to repair hail damage on metal roof systems, from the initial assessment to working directly with your insurance adjuster to ensure all damage is covered. As a family-owned business, we treat your home like our own, providing honest advice and high-quality workmanship.

Don’t let hail damage lead to more expensive problems. Whether you need a minor repair or a full assessment, we are here to help. Contact us today for a free, no-obligation estimate on your storm damage repairs and ensure your roof continues to protect your home for decades to come.