Why EPDM Roof Repair Illinois Matters for Your Commercial Property

EPDM roof repair Illinois is a critical service for maintaining the integrity of commercial and residential flat roofs. If you’re facing issues with your EPDM (Ethylene Propylene Diene Monomer) roof, understanding the repair process is key to protecting your investment.

Quick Answer: Common EPDM Roof Repairs in Illinois

- Puncture and tear patching: Small holes are repaired with EPDM patches extending at least 3 inches beyond the damage.

- Seam repair: Failed seams are re-adhered using specialized adhesives or heat-welded.

- Coating application: Reflective coatings are applied to protect against UV damage and extend roof life.

- Ponding water correction: Tapered insulation or improved drainage systems are installed to ensure proper water flow.

- Emergency leak repairs: 24/7 services are available for urgent issues caused by storms or hail.

Illinois’s extreme temperature swings, freeze-thaw cycles, and heavy snow can damage EPDM membranes over time. While EPDM is flexible and durable, regular inspections and timely repairs are essential to prevent small issues from becoming costly replacements. For reliable roofing solutions, homeowners and businesses trust our expertise.

I’m Gerald Michaels, founder of Adept Construction, Inc. Since 1997, my family-owned company has delivered superior workmanship on EPDM roof repair Illinois projects across Chicago’s western suburbs. We prioritize quality and customer satisfaction, building lasting relationships with our clients.

This guide covers everything from recognizing damage to understanding repair methods, costs, and choosing the right contractor. We’ll also share maintenance strategies to help your EPDM roof reach its full 25-30+ year lifespan.

What is EPDM Roofing and Why is it Ideal for Illinois?

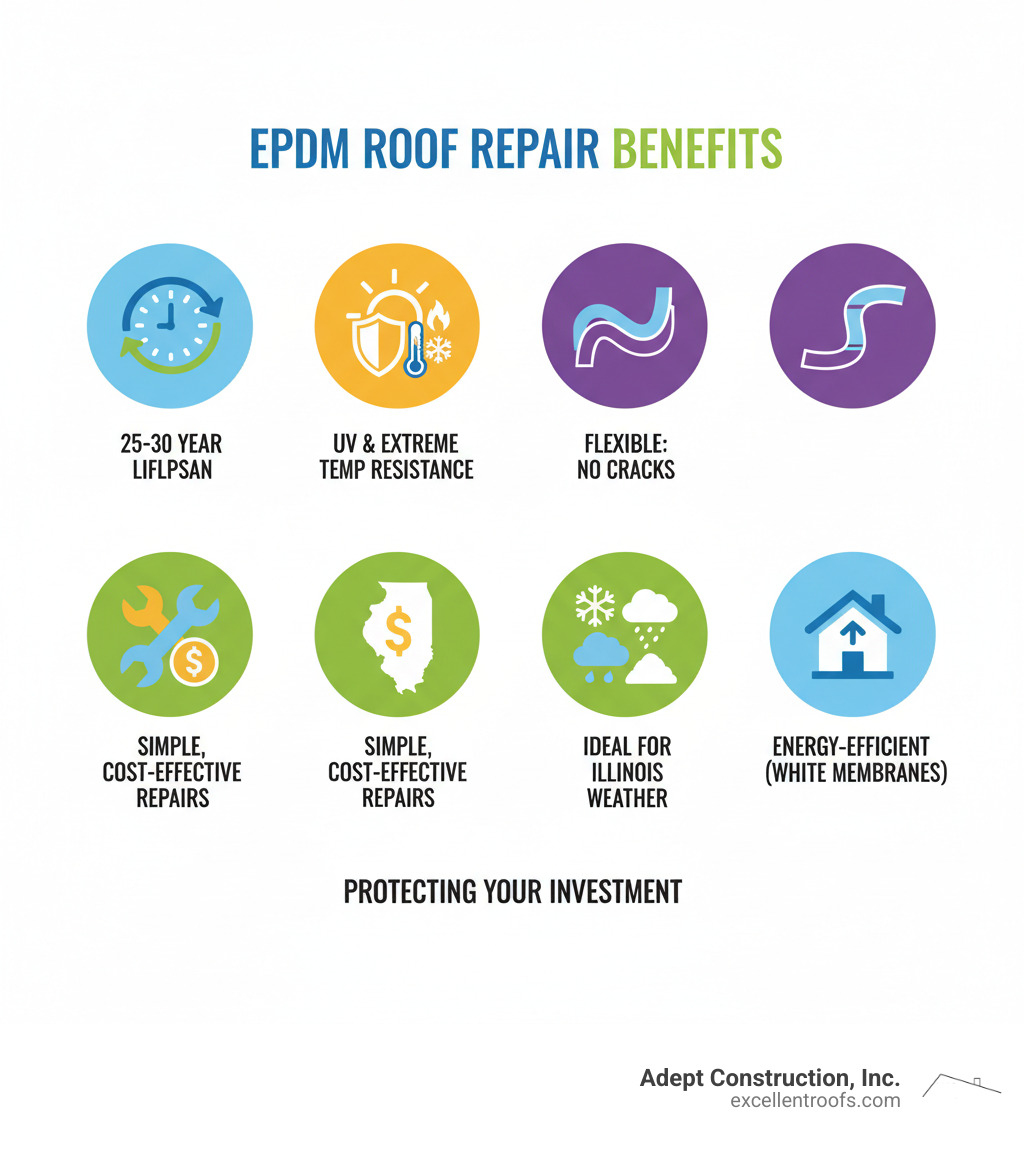

EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber membrane that has become a leading choice for flat and low-slope roofs in Illinois. Its popularity stems from three key benefits: durability, flexibility, and cost-effectiveness. With proper installation and maintenance, an EPDM roof can easily last 25 to 30 years or more, offering a strong return on investment.

EPDM is uniquely suited for Illinois’s demanding climate. The material boasts exceptional resistance to UV radiation, preventing degradation from the intense summer sun. More importantly, EPDM remains flexible in extreme temperatures, which is critical for surviving Illinois’s notorious freeze-thaw cycles. As water freezes and expands in small crevices—a process that destroys rigid materials—EPDM’s flexibility allows it to move without cracking or splitting.

This resilience also extends to heavy snow loads and hail damage, common challenges in our region. Furthermore, EPDM can improve energy efficiency. Traditional black EPDM absorbs solar heat, helping to reduce heating costs in the winter. For summer cooling, white EPDM options reflect sunlight, significantly lowering air conditioning expenses.

For property owners seeking reliable flat roofing systems that can withstand a temperamental climate, EPDM provides an ideal balance of performance and value. When the time comes for EPDM roof repair Illinois services, the material’s straightforward nature typically allows for more affordable and less disruptive repairs compared to other systems.

Recognizing the Red Flags: Common Signs Your EPDM Roof Needs Repair

Even the toughest EPDM roof will eventually show signs of wear, especially under the stress of Illinois weather. Catching problems early is the key to avoiding expensive, large-scale damage. Regular visual checks can mean the difference between a simple patch and a full roof replacement.

Here are the most common warning signs that your EPDM roof needs professional attention:

Visible Damage: Tears, punctures, or cuts from fallen branches, foot traffic, or wildlife are direct entry points for water.

Blisters and Bubbling: Raised areas indicate trapped air or moisture. If they rupture, they create an immediate leak risk.

Seam Separation: This is a critical failure point. When adhesives fail and seams pull apart, water can infiltrate the roofing system easily.

Membrane Shrinkage: Over time, the membrane can contract and pull away from flashing at walls or roof edges, creating gaps.

Ponding Water: Water that remains on the roof for more than 48 hours after rain signals a drainage issue, which accelerates wear and adds stress to the structure.

Interior Leaks or Water Stains: By the time you see water inside, the damage is already significant. Address these signs immediately. For help, see a complete guide to roof leak detection.

Membrane Deterioration: A chalky residue, surface cracking, or discoloration indicates the rubber is breaking down from UV exposure and age.

Spikes in Energy Bills: A compromised roof loses insulating effectiveness, forcing your HVAC system to work harder and driving up costs.

If you spot any of these red flags, don’t delay. Contact us for a free estimate to assess your roof’s condition before a minor issue becomes a major emergency.

The Complete Guide to EPDM Roof Repair in Illinois

Illinois weather presents a unique set of challenges for EPDM roofs. Freeze-thaw cycles stress seams, heavy snow loads test structural integrity, hail causes impact damage, and intense UV radiation degrades the membrane over time. Understanding these local factors is key to effective roof management.

A crucial decision for any property owner is whether to repair or replace a damaged roof. EPDM is highly repairable, making it an economical choice to maintain. Localized damage like punctures or isolated seam failures almost always warrants a repair. However, if the membrane is brittle, has widespread cracking, or is suffering from extensive adhesion failure, a full replacement may be the more cost-effective long-term solution. Our guide on do you need roof repair or replacement? can help you evaluate your options.

Common EPDM Roof Repair Methods and Processes

Precision is paramount in EPDM roof repair Illinois projects. The correct method is chosen based on the specific damage.

Patching Punctures and Tears: This is the most common repair. The process involves thoroughly cleaning the area with an EPDM-specific cleaner, applying a primer, and then adhering a patch that extends at least 3 inches beyond the damage. The patch is then rolled firmly to eliminate air bubbles and ensure a perfect seal. For technical details, resources like a detailed guide on warranty repairs are invaluable.

Seam Repair: Failed seams are repaired by cleaning and priming the area, then re-adhering the layers with specialized adhesives or using heat-welding techniques to create a monolithic bond.

Applying Roof Coatings: While not a fix for holes, reflective coatings can be applied over an aging roof to add a protective layer against UV degradation and weathering, significantly extending its life.

Drainage Correction: To fix ponding water, we may install tapered insulation to create a proper slope or add new drains to ensure water flows off the roof efficiently.

For property owners in Downers Grove, we offer specialized roof repair services in Downers Grove, IL for commercial and residential buildings.

The Importance of Timely EPDM Roof Repair in Illinois

Delaying roof repairs in Illinois is a costly gamble. Acting promptly provides numerous benefits:

- Prevents Water Infiltration: A small puncture can let in gallons of water, leading to mold, damaged insulation, and ruined inventory.

- Protects Structural Integrity: Chronic leaks cause wood to rot and steel to corrode, turning a simple repair into a major structural project.

- Maintains Energy Efficiency: A sealed roof is a crucial part of your building’s thermal envelope. Repairs stop conditioned air from escaping and lower utility bills.

- Extends Roof Lifespan: Addressing minor issues as they arise helps your EPDM roof reach its full 25-30 year potential.

- Avoids Costly Replacement: A few hundred dollars for a patch today can save you tens of thousands on a full replacement tomorrow.

- Ensures Compliance: Timely repairs keep you in compliance with building codes and insurance policies, preventing fines or denied claims.

Contact us today for a free estimate on your EPDM roof repair needs. We’ll provide an honest assessment and the most cost-effective solution.

Navigating the Financials and Finding the Right Pro

When your EPDM roof needs work, understanding the costs and finding a qualified professional are your top priorities. The goal is to find a fair price for expert work, not just the lowest bid.

Understanding the Costs of EPDM Roof Repair Illinois

There is no one-size-fits-all price for EPDM roof repair Illinois. Costs are determined by several factors:

- Extent of Damage: A single puncture is an affordable fix, while widespread seam failure requires significantly more labor and materials.

- Repair Method: A simple patch costs less than applying a full roof coating system or performing extensive heat-welding.

- Roof Accessibility: Difficult-to-access roofs that require special lifts or safety rigging will increase labor costs.

- Material Costs: Quality EPDM patches, primers, and adhesives fluctuate in price but provide superior longevity.

- Emergency Service: Urgent, after-hours repairs come at a premium compared to scheduled maintenance.

A reputable contractor will provide a detailed, itemized quote breaking down all costs. This transparency helps you compare bids accurately. For more tips, see our guide on getting free roofing estimates near you.

Choosing a Qualified EPDM Roofing Contractor in Illinois

Selecting the right contractor is simple if you focus on a few key qualifications:

- Licensed, Bonded, and Insured: This is non-negotiable. It protects you from liability for accidents or property damage.

- EPDM-Specific Experience: EPDM requires specialized knowledge. Hire a contractor who regularly works with rubber membranes, not a generalist.

- Local Expertise: A local contractor understands the specific challenges of Illinois weather. We have served communities like Naperville, IL and Downers Grove, IL for decades, giving us invaluable insight.

- Customer Reviews and References: Check Google reviews and ask for references from recent, similar projects. Positive feedback is a sign of professionalism and reliability.

- Strong Warranties: Look for a contractor who offers a solid workmanship warranty and uses materials backed by a strong manufacturer warranty.

- Clear Communication: A good contractor will explain the process clearly and answer all your questions without pressure.

Our essential checklist for choosing the right roofing contractor offers more in-depth guidance. As a family-owned company, we’ve built our reputation on the quality and service that earn strong local referrals.

Proactive Care: Extending Your EPDM Roof’s Lifespan

An EPDM roof is a major investment. Proactive maintenance is the best way to protect it and ensure it reaches its maximum 30+ year lifespan. A small issue caught during a routine inspection costs far less to fix than the extensive water damage from an ignored leak.

Here are the cornerstones of a smart EPDM roof maintenance plan:

Regular Professional Inspections: Schedule inspections twice a year (spring and fall) and after any major storm. A professional can spot early warning signs like minor punctures or lifting seams before they escalate.

Keep the Roof Clean: Debris like leaves and branches traps moisture against the membrane, which accelerates deterioration and can hide underlying damage. Regular cleaning prevents these issues.

Clear Drains and Gutters: Clogged drains are the primary cause of ponding water on flat roofs. This adds weight and stress to the structure. A simple quarterly check of all drainage systems can prevent this problem.

Address Minor Issues Promptly: Sealing small cracks, securing loose flashing, and reapplying sealant around vents are inexpensive fixes that prevent major water intrusion. These small tasks are the essence of preventative care.

Many property owners opt for professional maintenance plans, which bundle inspections, cleaning, and minor repairs into a predictable service. This approach takes the guesswork out of roof care. As detailed in the benefits of properly maintaining your roof, a well-cared-for roof is a long-lasting one.

Don’t wait for a leak to signal a problem. Schedule a free roof inspection with our team today to ensure your EPDM roof is in top condition.

Frequently Asked Questions about EPDM Roof Repair

Property owners in Illinois often have the same questions about their EPDM roofs. Here are answers to the most common inquiries we receive.

Can you repair an EPDM roof yourself?

While DIY repairs may seem cost-effective, they almost always cause more harm than good for EPDM roofs. Professional EPDM roof repair in Illinois is strongly recommended.

Proper repairs require specialized cleaners, primers, and adhesives that are not available at hardware stores. Applying them correctly is a science; improper application will fail. Furthermore, attempting a DIY fix will likely void your manufacturer’s warranty, leaving you responsible for the full cost of future failures. Finally, working on any roof carries significant safety risks. Professionals have the training and equipment to work safely, and they can identify hidden damage that a DIYer would miss. For more on this topic, see our article on why DIY roofing is a bad idea.

How long does an EPDM roof repair last?

A professionally executed EPDM roof repair can last for the remaining life of the roof. The longevity of a repair depends on two main factors: the quality of the workmanship and the quality of the materials used.

When a skilled technician uses manufacturer-approved materials and follows proper procedures for surface preparation and adhesion, the resulting patch or seam repair becomes an integral part of the roofing system. A well-done patch on a roof that is in otherwise good condition can easily last 15-20 years. The overall condition of the existing membrane also plays a role; repairs on a severely weathered roof may not last as long as those on a newer one.

Is EPDM roofing better than TPO for Illinois?

Both EPDM and TPO are excellent flat roofing systems for the Illinois climate. The best choice depends on your specific priorities and building needs.

EPDM’s primary advantage is its superior flexibility in cold weather. It withstands Illinois’s freeze-thaw cycles without becoming brittle, a quality proven over 50+ years of use. It is also typically lower in upfront material cost and highly repairable.

TPO’s main strengths are its heat-welded seams, which create a bond that is stronger than the membrane itself, and its high solar reflectivity. White TPO is an exceptional “cool roof” material, making it ideal for property owners focused on reducing summer cooling costs.

For many in Illinois, EPDM’s proven cold-weather performance gives it an edge. However, if maximum seam strength or energy efficiency in summer are your top concerns, TPO may be the better option. We can help you assess your property and make the right choice.

Conclusion

Your EPDM roof is a critical asset, protecting your property from Illinois’s demanding weather. As we’ve covered, this durable material can last for decades, but only with proper care. Understanding the signs of damage and the importance of timely, professional repairs is the key to maximizing your roof’s lifespan and avoiding costly problems.

EPDM roof repair Illinois is a manageable process when you have a trusted partner. Whether it’s a small puncture or a failing seam, professional attention ensures a long-lasting solution, not just a temporary fix.

As a family-owned company serving the Chicago western suburbs since 1997, Adept Construction, Inc. has built its reputation on superior customer service and high-quality workmanship. We treat every roof as if it were our own, bringing decades of experience to every project. We believe in educating our customers and providing transparent communication, so you feel empowered to make the best decisions for your property.

Don’t wait for a minor issue to escalate into a structural threat. Protect your investment with proactive care from a team that values your building’s health. We offer free, no-obligation estimates for all roofing projects.

Ready to give your EPDM roof the expert attention it deserves? Contact us today for a free estimate and let us ensure your roof continues to protect what matters most for years to come.